Industry Track RecordContact Us

Through real-time factory monitoring via system interface, implementing convenient mobile management, improving efficiency and streamlining manpower, we transform current situations such as manual production records and machine status checking that require physical inspection into smart connected network systems with real-time digital management.

Automotive and Parts Manufacturing

Textile Industry

Metal Products and Parts Manufacturing

Bicycle Components Industry

Non-metallic Furniture and Fixtures Manufacturing

Chemical and Pharmaceutical

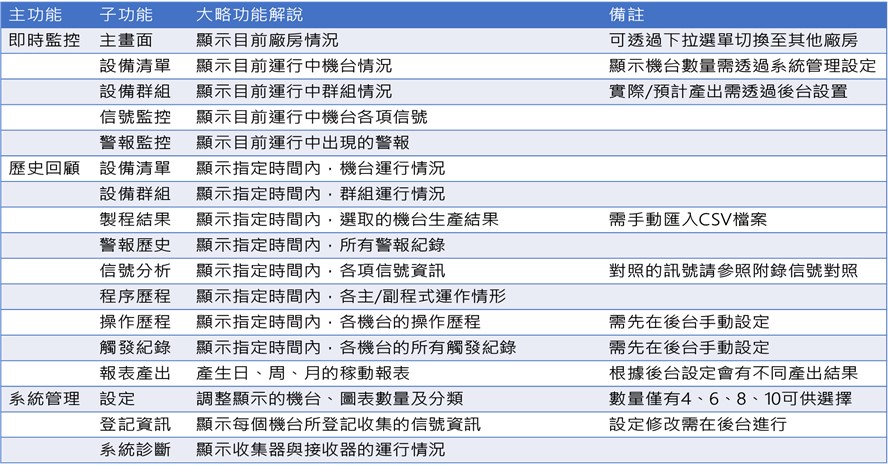

Equipment MonitoringContact Us

Facteye is a machine networking system that uses intuitive visual charts to help managers monitor production status in real-time. The system supports production data collection from various equipment including CNC machines, PLCs, and robotic arms. It converts collected data into analytical management information such as equipment utilization rates, production history, and completion metrics to improve equipment management transparency, accuracy, and utilization rate, strengthening enterprise competitive advantages.

Additionally, Facteye can be applied to preventive maintenance of production equipment, including automated machine failure notifications and setting alert ranges for key operational data. When data exceeds the set range, it notifies managers, effectively improving alarm communication efficiency and reducing downtime.

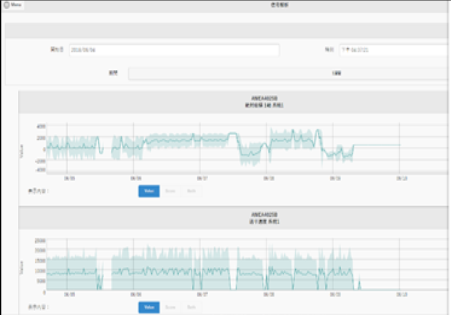

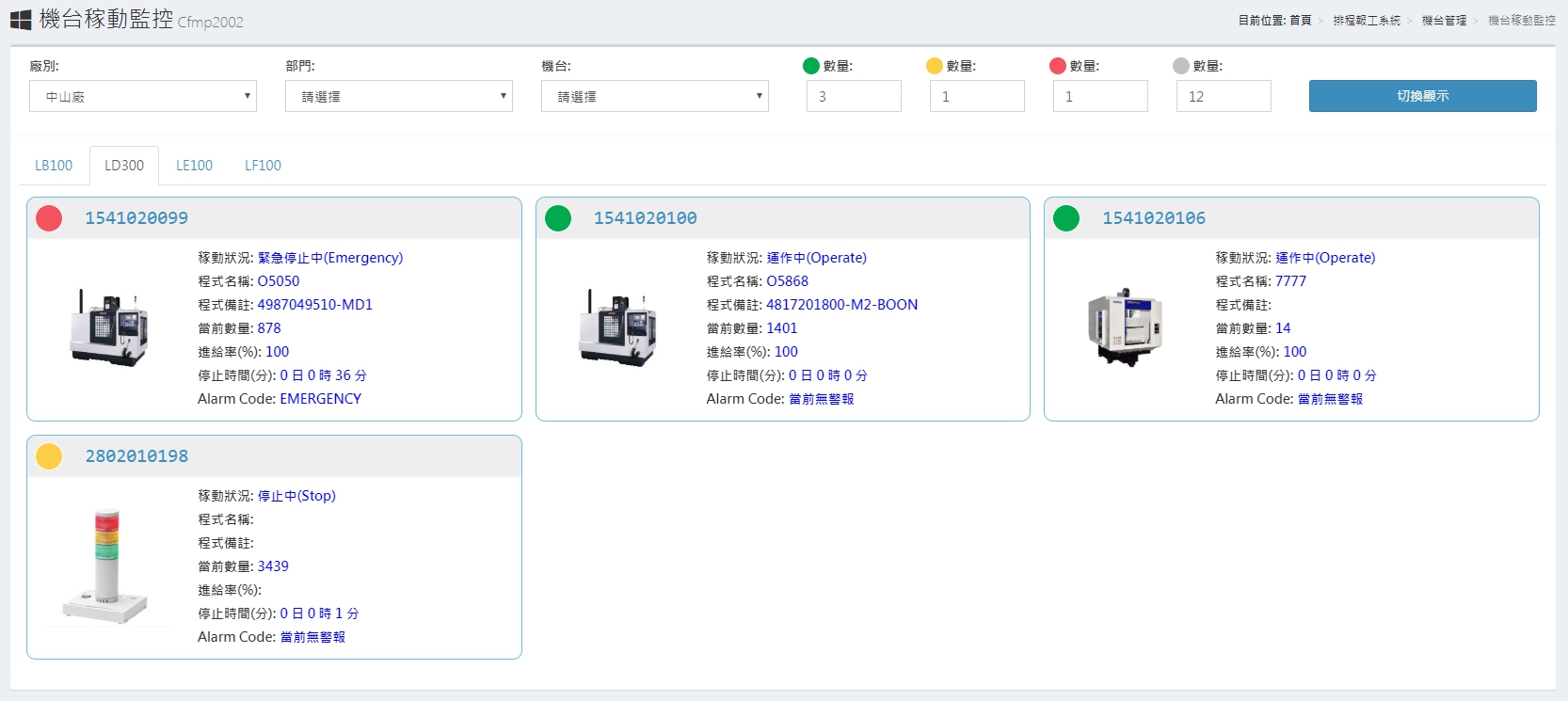

Machine Status and Time Information Recording Interface

Displays various operational states of individual machines, including running programs, cutting time, temperature, current values, and other information that can be used for energy management and tool wear monitoring.

Data can be stored for future maintenance and operational history queries.

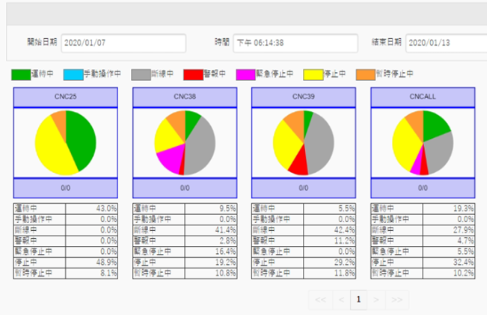

Time Distribution of Various Operating States

Machine utilization can be monitored individually or in groups according to management needs, providing insights into the actual operational status of each machine. Production lines can be defined as groups for deeper understanding of actual production line utilization data, eliminating manual recording time and calculation errors.

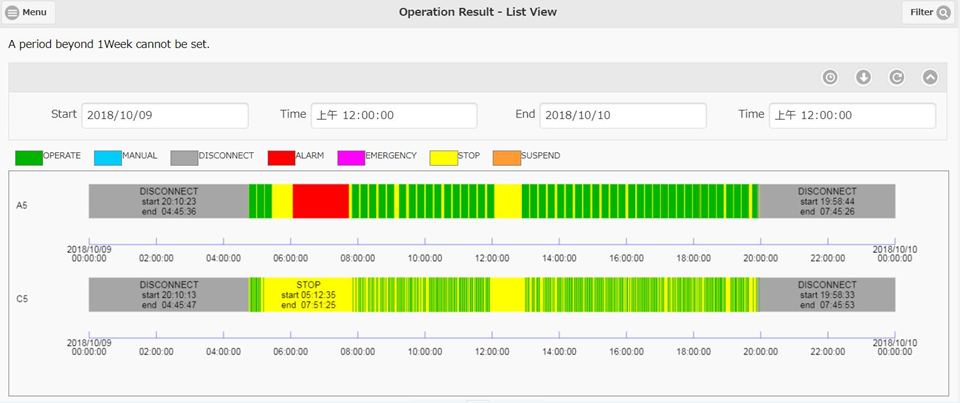

Machine Operation Timeline Recording Interface

The machine operation timeline allows review of equipment operational status, using color-coding to identify more than six operating states, and enables viewing of machine operations within specified time periods. The operation bar can be zoomed in to view status at one-minute intervals.

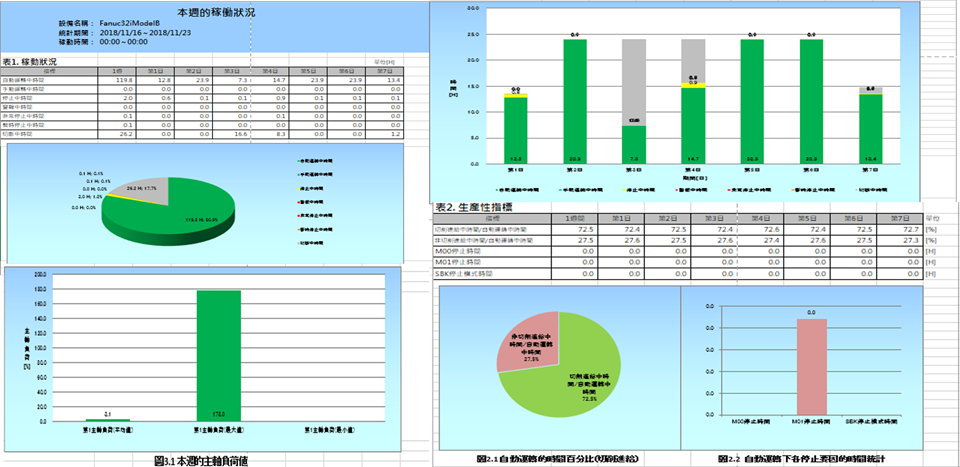

Daily, Weekly, and Monthly Report Generation

Historical review can be conducted by machine, providing daily, weekly, and monthly report generation. This function can be manually or automatically exported through the backend system.

| Fanuc | Mitsubishi | Toshiba | Mazak | Brother | Okuma | PLC |

|---|---|---|---|---|---|---|

|

|

|

|

|

|

|

Production DashboardContact Us

Operation Monitoring Platform

Dashboard & Production Progress

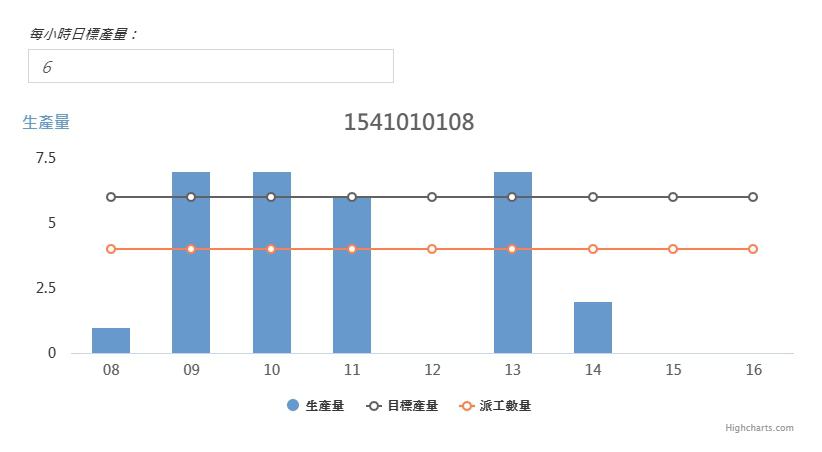

Hourly production targets can be set for each equipment, and production progress standard lines can be drawn from ERP and MES systems to clearly understand if equipment meets hourly production targets.

Dashboard & Capacity Dashboard

Based on real-time processing data from equipment and ERP/MES systems, displays work order numbers and processes for each equipment. Data is calculated to show production efficiency percentages, allowing production management personnel and supervisors to better understand real-time production efficiency of each machine.

Program TransferContact Us

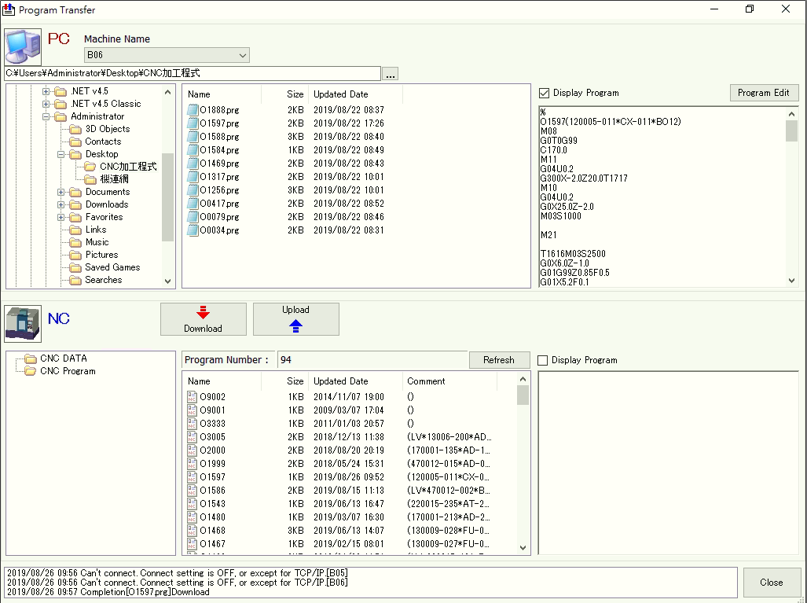

- 1. Upload and download machining programs for networked Fanuc CNC.

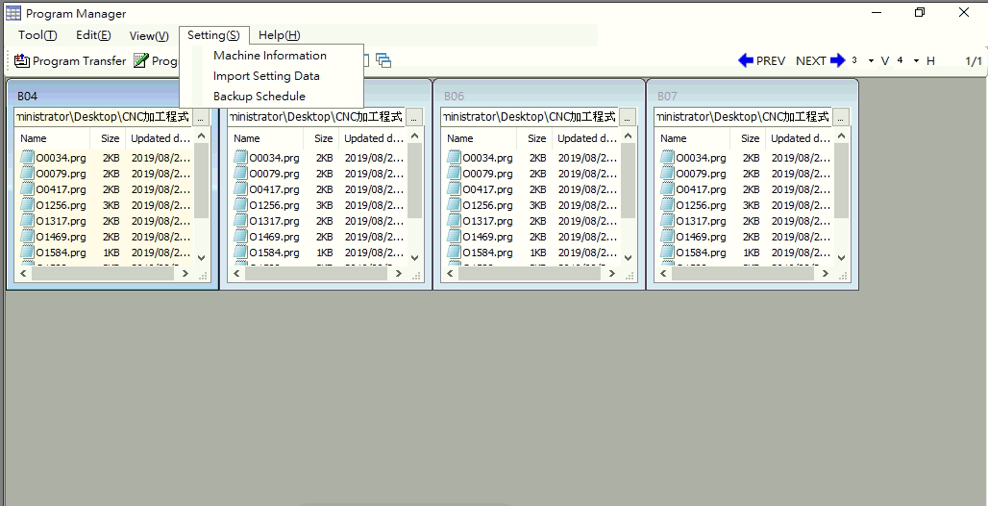

- 2. Specially designed interface for program management.

- 3. Special program management system for easy control of multiple CNC programs.

- 4. Manage CNC internal programs through upload/download functions.

Scheduling and Work ReportingContact Us

The main function of the scheduling and work reporting system is to complement features not available in general ERP production modules. Typically, ERP only provides production order generation and completion warehousing, without clear assignment of orders to specific machines on the floor - the so-called work dispatching.

Therefore, the scheduling and work reporting system provides ERP order data integration, order dispatching to shop floor machines, and production completion status reporting. Through these processes and functions, floor staff and production control personnel can more effectively query the production status of each order, thereby improving work efficiency and eliminating manual hours spent on traditional paper-based dispatch records/queries.

Feature List

Company Settings: Provide company data configuration

Department Category Settings: Provide department category data configuration

Department Settings: Provide department information configuration

Employee Category Settings: Provide employee category data configuration

Employee Data Settings: Provide employee basic data configuration

Customer Category Settings: Provide customer category data configuration

Customer Data Settings: Provide customer basic data configuration

Vendor Category Settings: Provide vendor category data configuration

Vendor Data Settings: Provide vendor basic data configuration

Factory Settings: Provide factory data configuration

Machine Settings: Provide machine data and icon configuration

Process Settings: Provide process basic data configuration

Part Number Settings: Provide part number, image, and processing flow configuration

Order Maintenance: Provide order information configuration and import functionality

Work Order Generation: Convert order data into work orders

Work Order Query: Provide work order data inquiry

Work Order Process Modification: Modify work order processing flow with record keeping

Scheduling Operations: Arrange work order processing sequence for machines

Production Reporting: Report actual processing time, quantity, and personnel for work orders

Machine Utilization Monitoring: Real-time machine production status monitoring

Work Dispatch Form: Print blank forms for on-site production record keeping

Mini Order: Print relevant work order information

Machine Production Status Report: View completed and incomplete work orders by machine

Employee Production Status Report: View completed and incomplete work orders by employee

Order Production Status Report: View completed and incomplete work orders by order

Product Production Status Report: View completed and incomplete work orders by product

Tool Life ManagementContact Us

Tools are essential components in CNC machining and represent expensive consumable resources. With numerous tools of various types, management and maintenance can be challenging. Without advance knowledge of remaining tool life, preventive replacement becomes difficult, and discovering parts at their life limit could lead to machine damage or irreversible harm.

ISCOM's Tool Life Management utilizes native CNC machine data for calculations, requiring no additional modifications or equipment installations.

Management Methods

| Method 1 | Method 2 | Method 3 |

|---|---|---|

| CNC Program Tool Usage Count | Modified Equipment PLC Usage Count | Tool XY Axis Travel Distance |

| Reads T-code usage count from CNC equipment and compares with usage experience and tool usage count to provide tool replacement reminders. | Calculates tool operation point usage count from modified PLC equipment and compares with usage experience to provide tool replacement reminders. | Reads X or Y axis travel distance from CNC equipment and compares with usage experience to provide tool replacement reminders. |

Preventive MaintenanceContact Us

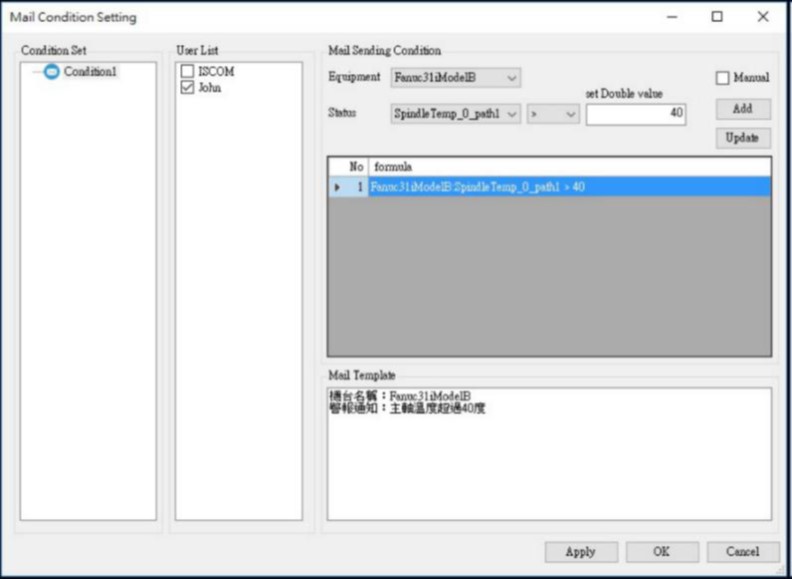

Can store and email CNC/PLC equipment alarm signals to determine alarm types and occurrence times. Equipment data threshold ranges can be set as basis for alarms and preventive maintenance.

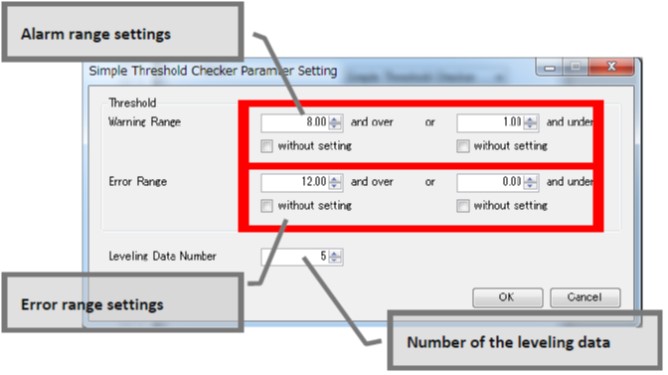

Fault notification content can be configured. When exceeding warning/error ranges, immediate notifications are sent (via email). Component usage time can be tracked for maintenance and replacement reminders (preventive maintenance).

Alarm Range Settings

The alarm range setting interface allows configuration of upper and lower limits based on equipment signals for alarm triggering and email notifications.

Fault Notification Settings

Fault notification settings allow configuration of alarm level notification ranges, machine alarm email addresses, and machine data threshold notification settings.